I-Beam Levels vs. Box Beam: What’s the Difference?

If you’re doing any type of construction job, you’ll need a level at some point in the process. A level can help you determine if something is true, plumb or level and will help ensure the accuracy of your finished project.

When the time comes to purchase a level, you’ll notice that there are many different styles and options to choose from. Some levels are designed for very specific uses, while others are designed to be more of an all-purpose tool.

Two of the most common styles of level include the I-Beam and the box beam. Both will give you accurate results, but they do have some differences you should know about before making a choice. Learn what these differences – and similarities – are to make the most informed decision about which level will best suit your needs.

Construction

The biggest difference between an I-Beam level and a box beam level is in their construction.

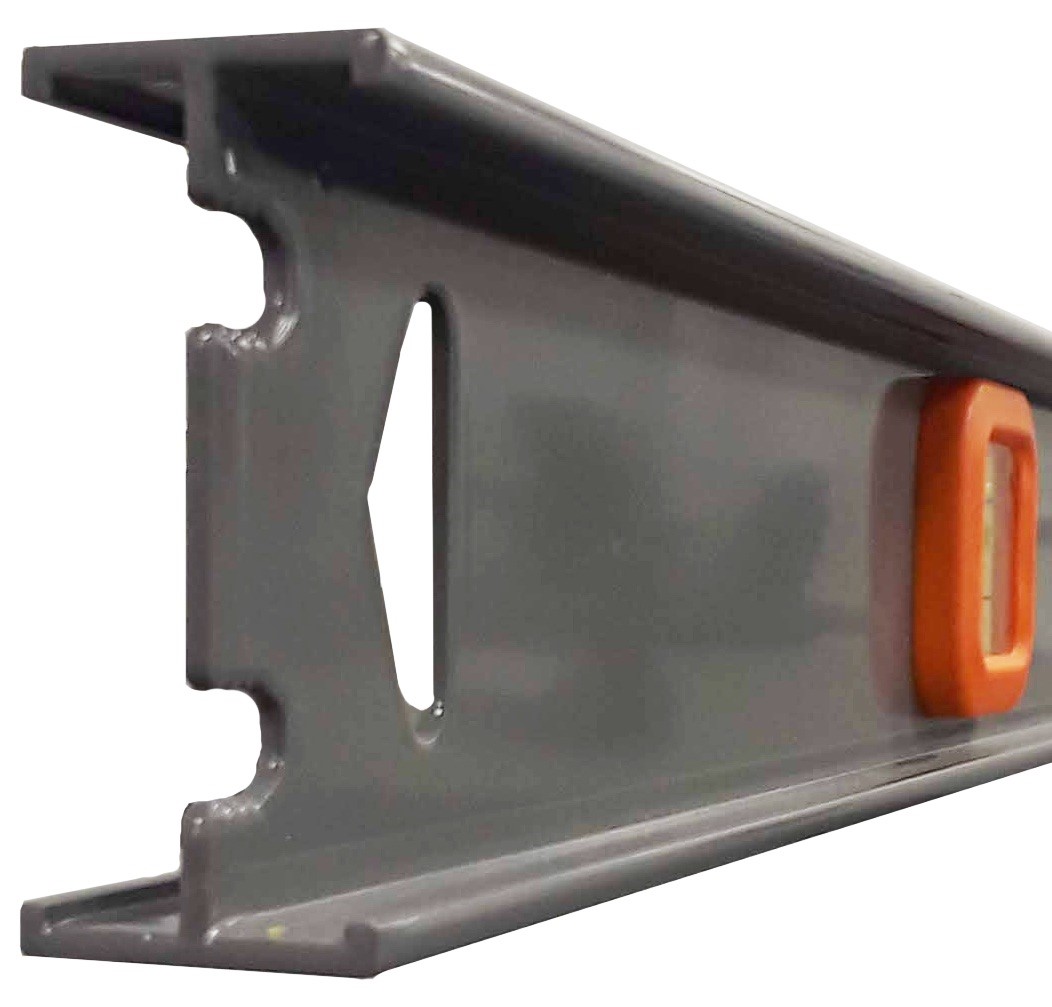

If you were to cut an I-Beam level in half and turn it so you were looking down its length, its shape would be that of a capital I. The long, horizontal pieces at the top and bottom of the level are called flanges, and the thin, interior section that holds the spirit levels is called the web. The I-Beam level is designed this way to make it lightweight. I-Beam levels are often fitted with tube vials, which can be more susceptible to damage than acrylic vials if not properly handled.

A box beam level also gets its name from its shape. In this case, the level is built like a box, usually with handles or grips towards the center to make it easier to hold. Good quality box beam levels have a solid construction, featuring an extra-strong profile which is seen in the thickness of the walls. The thicker the walls, the sturdier the level. Some can also have a heavy profile weight to make sure it can hold up to heavy usage without compromising the level.

Durability

When it comes to the durability of either level, the material it’s made from is the biggest contributing factor. A box beam that is solid in construction and made of acrylics or aluminum will be more durable overall than an I-Beam, as the extra, solid material makes it more difficult to bend, crack, twist or break over time.

I-Beam levels are made from lighter materials, so it’s more prone to cracks and breaks, though the end caps can help provide some protection in the event of accidents and drops. When checked regularly for accuracy and reserved for general, non-strenuous uses, you can increase the life of your I-Beam level.

Use

I-Beam and box beam levels are used identically. They both contain spirit levels that give accurate reads. Though the I-Beam’s vials are normally not as sturdy, they can take both the level and plumb of an object efficiently.

Both types of levels also come in several sizes, so you can find one to fit your purpose. It’s also possible to find both I-Beam and box beam levels with a magnetic option, letting you easily attach them to a metal surface while you take the reading.

Of the two, the I-Beam is lighter in weight, which in some instances may make it easier to use if it’s being held or carried over a longer period of time. The shape of the level makes it fairly easy to hold, as the level itself is fairly thin. Some may have a handgrip towards the center as well.

Box beams that are completely solid may be slightly more difficult to hold. The shape requires a different grip, and a solid box beam will be heavier as well.

However, many quality box beam levels are designed with comfortable hand grips to make them easier to hold and use. These grips go through the center of the level, making the tool a little easier to hang onto in a busy job site. Some quality box beams are also designed with lighter-weight materials, giving you the best of both worlds: durability and ease of use.

Get the Right Level

Both an I-Beam and a box beam level will give you an accurate reading that will help you get your project done right. When both are made from quality materials and designed with the user in mind, they will both be easy to use, carry and grasp.

Selecting an I-Beam level or a box beam level will depend on the job you’re doing and the level of accuracy and durability your project demands. Be sure to examine the specifications of each when making your decision so that your project can be constructed as seamlessly and efficiently as possible.

If you want quality levels that will last for years, check out Keson’s line of levels. Made with SOLA FOCUS vials, these levels will provide you with an accurate reading, every time.